Chem-X® Pleated Filter

Chem-X® Pleated Filter

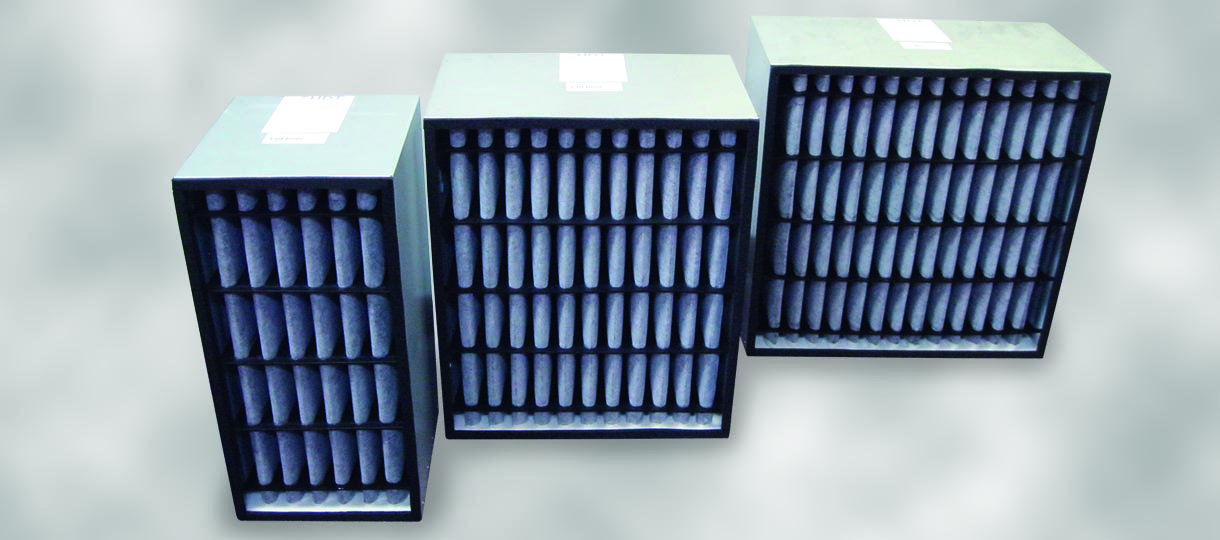

HDT’s Chem-X® pleated filter provides high-efficiency, single-pass filtration of gas-phase contaminants. It is designed to remove gaseous chemical agents and can be used in new and existing commercial HVAC systems, over-pressurization systems, and negative isolation systems that demand highly efficient chemical filtration, along with low pressure drop.

The Chem-X pleated filter is manufactured using deep-pleated carbon media housed in a modular corrosion-resistant 24-gauge galvanized steel housing. HDT Chem-X pleated filters are manufactured under rigorous quality control procedures. Every filter is factory leak-tested to ensure the integrity of the manufactured cell. Additionally, each filter lot is subjected to destructive lot testing, in which filters are randomly selected and submitted for dimethylmethylphosphonate (DMMP) breakthrough testing where the filtration efficiency requirement is 2,500:1. DMMP is a chemical agent simulant used extensively by the U.S. Army to simulate the performance of Sarin and other nerve and blister agents.

HDT Chem-X carbon filter units are available in three standard sizes to fit most popular commercial HVAC filter compartments.

- High flow designs from 800 CFM to 2,000 CFM (1,360 to 3,400 m3/min)

- Low air flow resistance <1.0 IWG (249 Pa)

- Much lower unit cost and much lighter than traditional packed-bed adsorbers

- 100% factory leak-tested using refrigerant (R134a)

- Stringent DMMP Lot Acceptance testing conducted all production lots

- Nominal 24" (60.96 cm) H x 24" (60.96 cm) W and standard 12" (30.48 cm) depth allows for easy, low cost installation into existing housings, or for new filtration applications

- Available in three different widths: 12" (30.48cm), 20" (50.8 cm), and 24" (60.96 cm)