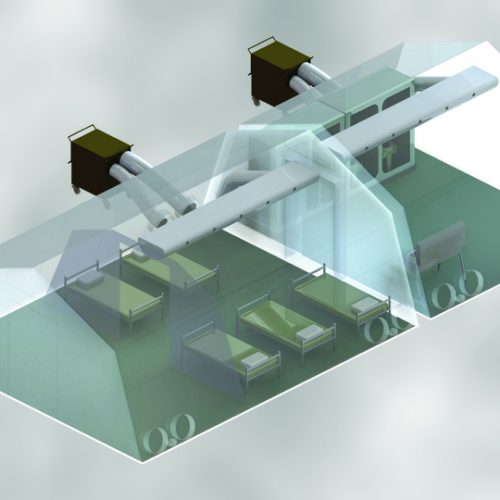

HDT Medical Shelter System – Patient Isolation

HDT Global is the world leader in expeditionary shelter systems. Designed for a variety of applications, HDT has a shelter solution for every requirement; from personnel billeting, tactical operations centers, equipment warehousing, vehicle maintenance to point-of-delivery and casualty and disease response solutions. HDT engineers and manufactures AirBeam®, Base-X® and DRASH® soft wall shelter systems and Berg™ rigid wall shelter systems.

HDT expeditionary shelter systems and completely-configured base camps work seamlessly with HDT power generation, heating and cooling, and protective air filtration systems.