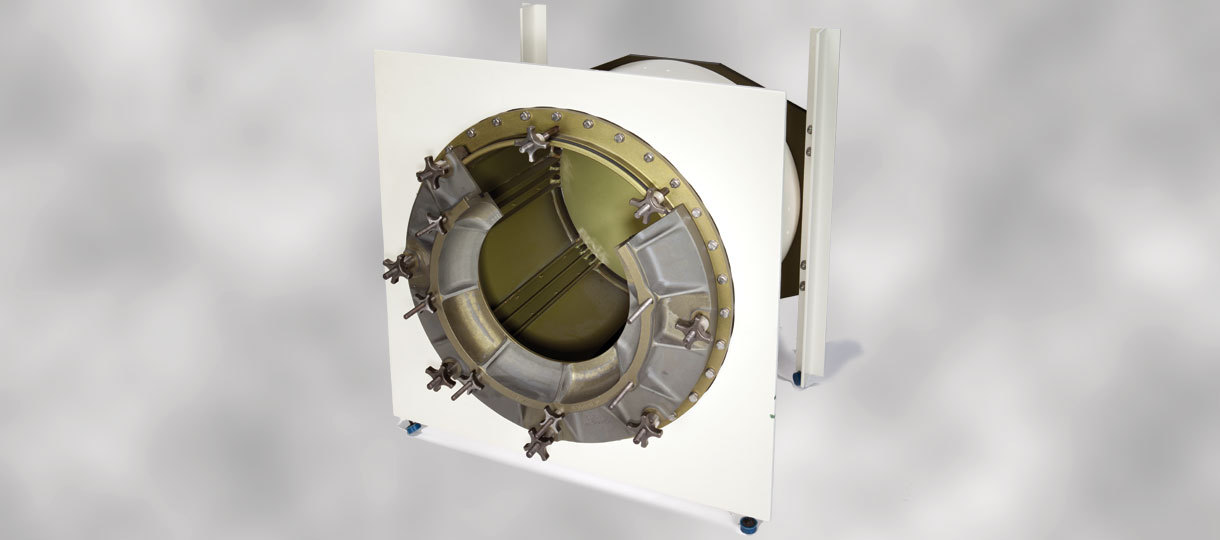

CBR Filter Housing, U.S. Navy

The U.S. Navy CBR filter housing is used in ship collective protection systems (CPS) to remove chemical, biological and radiological (CBR) contaminants from outside makeup air. These aluminum filter housings hold from one to five M98 particulate/gas filter sets for airflow rates up to 1,000 CFM (1699 m3/h) per housing. They have been qualified to military shock and vibration standards for shipboard use. They are constructed of aluminum and anodized for maximum corrosion resistance in marine environments.

- An integral part of ship collective protection systems, U.S. Navy CBR filter housings are designed to house M98 particulate/gas filter sets for removal of toxic CBR agents under the harshest environmental conditions. They are qualified to high-impact military shock (Mil-S-901) and vibration (Mil-Std-167) in housing lengths up to five (5) filters deep.

- The U.S. Navy CBR filter housing features a two-piece front cover for independent tightening of M98 gas and particulate filter stacks

- The gas cover, or outer ring, mounts to the front of the housing, while the inner HEPA cover mounts to the gas cover

- Covers are secured using spring-loaded nuts with indicators that recess when the proper torque is achieved

- Filter housings are constructed from aluminum and anodized for maximum corrosion resistance. They are available painted with military-grade epoxy paint.

- Often installed in “banks” for greater flow capacities, with ship applications these banks are located upstream of ventilation supply fans for “pull-through” airflow. Air leaving the filter housings flows into an outlet plenum through slots in the back of the housing.

- With thousands of units built, installed and operating on a full-time basis, HDT’s U.S. Navy CBR filter housing has emerged as a proven standard for collective protection systems